ISO 16559: 2014 Solid Biofuels, Uncategorized

ISO 16559: 2014 Solid biofuels 4

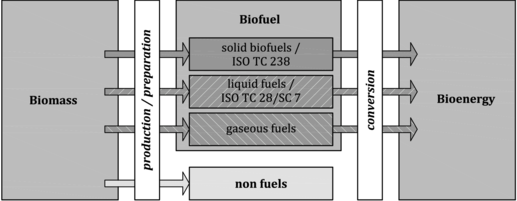

Courtesy: ISO 16559: 2014 Solid biofuels

Estimates about the climate impact from biofuels vary widely based on the methodology and exact situation examined.

In general, biofuels emit fewer greenhouse gas emissions when burned in an engine and are generally considered carbon-neutral fuels as the carbon emitted has been captured from the atmosphere by the crops used in production. However, life-cycle assessments of biofuels have shown large emissions associated with the potential land-use change required to produce additional biofuel feedstocks. A review of 179 studies published between 2009 and 2020 found that if no land-use change is involved, first-generation biofuels can—on average—have lower emissions than fossil fuels. Second-generation biofuels have a greater potential to reduce the emissions, but also require that their production does not cause any land-use change. Third-generation biofuels generate more greenhouse gas emissions than those from fossil fuels and are generally not considered a feasible option.

Several studies have also shown that reductions in emissions from biofuels are achieved at the expense of other impacts, such as acidification, eutrophication, water footprint and biodiversity loss.

Types

The following fuels can be produced using first, second, third or fourth-generation biofuel production procedures. Most of these can be produced using two or three of the different biofuel generation procedures.

Gaseous

Biogas and biomethane

Biogas is methane produced by the process of anaerobic digestion of organic material by anaerobes. It can be produced either from biodegradable waste materials or by the use of energy crops fed into anaerobic digesters to supplement gas yields. The solid byproduct, digestate, can be used as a biofuel or a fertilizer. When CO2 and other impurities are removed from biogas, it is called biomethane.

Biogas can be recovered from mechanical biological treatment waste processing systems. Landfill gas, a less clean form of biogas, is produced in landfills through naturally occurring anaerobic digestion. If it escapes into the atmosphere, it acts as a greenhouse gas.

Farmers can produce biogas from manure from their cattle by using anaerobic digesters.

Syngas

Syngas, a mixture of carbon monoxide, hydrogen and various hydrocarbons, is produced by partial combustion of biomass, that is, combustion with an amount of oxygen that is not sufficient to convert the biomass completely to carbon dioxide and water. Before partial combustion, the biomass is dried, and sometimes pyrolysed. The resulting gas mixture, syngas, is more efficient than direct combustion of the original biofuel; more of the energy contained in the fuel is extracted.

Syngas may be burned directly in internal combustion engines, turbines or high-temperature fuel cells. The wood gas generator, a wood-fueled gasification reactor, can be connected to an internal combustion engine.

Syngas can be used to produce methanol, DME and hydrogen, or converted via the Fischer–Tropsch process to produce a diesel substitute, or a mixture of alcohols that can be blended into gasoline. Gasification normally relies on temperatures greater than 700 °C.

Lower-temperature gasification is desirable when co-producing biochar, but results in syngas polluted with tar.