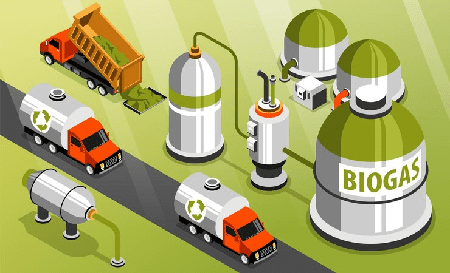

Bio Gas Plant

Bio Gas Plant

A biogas plant, also known as a biogas digester or anaerobic digestion plant, is a facility that converts organic materials such as agricultural waste, food scraps, animal manure, and sewage into biogas through a process called anaerobic digestion. Biogas is a mixture of primarily methane and carbon dioxide, along with small amounts of other gases such as hydrogen sulfide and ammonia.

The process of anaerobic digestion occurs in the absence of oxygen and involves microorganisms breaking down organic matter. This process produces biogas, which can be used as a renewable energy source for heating, electricity generation, or as a vehicle fuel. Additionally, anaerobic digestion also produces a nutrient-rich byproduct called digestate, which can be used as a fertilizer.

Biogas plants can vary in size and complexity, from small-scale systems used by individual farms or households to large industrial facilities that process significant quantities of organic waste. The design of a biogas plant depends on factors such as the types and quantities of feedstock available, the desired output of biogas, and the intended use of the digestate.

Overall, biogas plants offer numerous environmental benefits by reducing greenhouse gas emissions, managing organic waste, and providing renewable energy sources. They also contribute to sustainable agricultural practices by recycling nutrients and reducing dependence on fossil fuels.

Whate Is Required Bio Gas Plant

To establish a biogas plant, several key components and requirements are necessary. Here’s a basic outline of what is typically needed:

- Feedstock: Organic materials such as agricultural waste (crop residues, animal manure), food waste, sewage, and energy crops (like maize or energy grasses) are required as feedstock for the biogas plant. The availability and type of feedstock will influence the design and scale of the plant.

- Anaerobic Digester: This is the core component where the anaerobic digestion process takes place. The digester can be of various types, including batch, continuous stirred-tank reactors (CSTR), plug flow, or fixed film digesters. The choice depends on factors such as feedstock type, plant size, and desired biogas output.

- Microbial Inoculum: Inoculum containing microorganisms responsible for anaerobic digestion is often added to kick-start the process, especially for new plants. This inoculum helps establish the microbial community necessary for efficient biogas production.

- Gas Collection System: A mechanism for collecting and storing the biogas produced during anaerobic digestion is essential. This usually involves a gas holder or dome that floats on top of the digester, allowing for the capture and storage of biogas.

- Gas Treatment System: Biogas typically contains impurities such as moisture, hydrogen sulfide (H2S), and other trace gases. Therefore, a gas treatment system, which may include scrubbers, desulfurization units, and moisture removal systems, is required to purify the biogas before it can be utilized.

- Biogas Utilization System: Biogas can be used for various purposes, including electricity generation, heat production, or vehicle fuel. Depending on the intended use, appropriate conversion systems such as biogas engines, turbines, or boilers are required.

- Digestate Management: The solid and liquid residues left after anaerobic digestion, known as digestate, need to be managed properly. Digestate is rich in nutrients and can be used as a fertilizer or soil conditioner. Storage, treatment, and application methods for digestate should be considered.

- Safety Measures: Safety measures such as gas leak detection systems, ventilation, and emergency shutdown procedures are essential to ensure the safe operation of the biogas plant and protect workers and nearby communities from potential hazards.

- Regulatory Compliance: Compliance with local regulations and permitting requirements related to environmental, health, safety, and waste management is crucial for the establishment and operation of a biogas plant.

- Monitoring and Maintenance: Regular monitoring of process parameters, equipment performance, and maintenance activities are necessary to optimize biogas production, ensure system reliability, and prolong the lifespan of the plant.

Overall, successful implementation of a biogas plant requires careful planning, design, and management to effectively convert organic waste into renewable energy and valuable byproducts while minimizing environmental impact and ensuring safety and regulatory compliance.

Who is Required Bio Gas Plant

Establishing and operating a biogas plant typically involves various professionals with different expertise and roles. Here’s a list of key individuals or teams typically involved:

- Project Manager: Oversees the entire project, including planning, design, construction, and operation phases. Coordinates with various stakeholders and ensures that the project meets its objectives within budget and schedule.

- Biogas Engineer: Responsible for designing the biogas plant layout, selecting appropriate anaerobic digestion technology, sizing equipment, and optimizing process parameters for efficient biogas production.

- Environmental Engineer: Assesses potential environmental impacts of the biogas plant and ensures compliance with environmental regulations. Designs systems for managing waste streams and mitigating emissions.

- Civil Engineer: Designs civil structures such as digester tanks, gas storage facilities, and waste treatment systems. Ensures structural integrity and safety of the infrastructure.

- Mechanical Engineer: Designs mechanical systems including pumps, mixers, gas handling equipment, and power generation systems. Ensures proper functioning and integration of mechanical components.

- Electrical Engineer: Designs electrical systems for power distribution, control, and instrumentation. Selects and installs electrical equipment such as generators, motors, and monitoring devices.

- Biologist/Microbiologist: Provides expertise on microbial ecology and anaerobic digestion processes. Helps optimize process conditions, troubleshoots issues related to microbial activity, and assesses the quality of digestate.

- Chemical Engineer: Designs systems for gas treatment, including removal of impurities such as hydrogen sulfide and moisture. Optimizes chemical processes for gas purification.

- Regulatory Specialist: Ensures compliance with local, state, and national regulations related to environmental permitting, safety standards, and waste management. Submits necessary permits and documents for regulatory approval.

- Construction Team: Carries out construction activities based on the design specifications. Includes skilled laborers, equipment operators, and supervisors responsible for site preparation, excavation, concrete work, and installation of equipment.

- Operations and Maintenance Staff: Responsible for day-to-day operation, monitoring, and maintenance of the biogas plant. Includes operators, technicians, and maintenance personnel who ensure proper functioning of equipment, troubleshoot issues, and perform routine maintenance tasks.

- Quality Control and Assurance Personnel: Monitors process performance, analyzes biogas and digestate quality, and ensures adherence to quality standards and operational protocols.

- Financial Analyst/Manager: Assesses project feasibility, prepares cost estimates, secures funding or financing options, and manages project budget and financial resources.

Collaboration among these professionals is essential for the successful planning, design, construction, and operation of a biogas plant. Additionally, stakeholders such as investors, regulatory agencies, local communities, and potential feedstock suppliers may also be involved in various stages of the project.

When is Required Bio Gas Plant

The need for a biogas plant arises in situations where there is a desire to manage organic waste effectively while also harnessing renewable energy sources. Here are some scenarios where a biogas plant might be required:

- Agricultural Operations: Farms with livestock produce significant amounts of manure, which can be a source of environmental pollution if not managed properly. A biogas plant can help farmers convert this waste into energy while also reducing odors and pathogens.

- Waste Management: Municipalities and waste management companies often seek sustainable solutions for managing organic waste, such as food scraps and sewage sludge. Biogas plants offer a way to divert this waste from landfills and utilize it for energy production.

- Energy Generation: Regions looking to diversify their energy sources and reduce reliance on fossil fuels may invest in biogas plants to generate electricity or heat. Biogas can be used to power generators, boilers, or combined heat and power (CHP) systems.

- Environmental Compliance: Industries that produce organic waste as a byproduct of their operations may need to comply with environmental regulations regarding waste management and emissions. Installing a biogas plant can help these industries meet regulatory requirements while also reducing their carbon footprint.

- Rural Development: In rural areas with limited access to centralized energy grids, biogas plants can provide a decentralized energy solution. This can contribute to rural development by providing electricity and heat for local communities and businesses.

- Sustainability Goals: Organizations committed to sustainability and reducing greenhouse gas emissions may incorporate biogas production as part of their environmental initiatives. Biogas plants offer a renewable energy source that can help mitigate climate change.

- Resource Recovery: Biogas plants not only produce renewable energy but also generate nutrient-rich digestate, which can be used as organic fertilizer. This closed-loop approach to waste management helps conserve resources and support agricultural productivity.

- Economic Benefits: Biogas production can create economic opportunities by generating revenue from the sale of electricity, heat, or biogas-derived products. Additionally, cost savings may be realized through reduced waste disposal fees and potential incentives or subsidies for renewable energy projects.

The specific timing for when a biogas plant is required depends on various factors, including local regulations, waste management challenges, energy needs, economic viability, and community priorities. In many cases, proactive planning and assessment of these factors can help identify opportunities for implementing biogas projects to address specific needs and goals.

Where is required Bio Gas Plant

Biogas plants can be required and beneficial in various locations and contexts. Here are some scenarios where biogas plants might be needed:

- Agricultural Areas: Farms with livestock, such as dairy farms, hog farms, and poultry farms, often generate significant amounts of organic waste in the form of manure. Biogas plants in these locations can help manage the waste while also producing renewable energy and reducing odor and environmental pollution.

- Urban and Suburban Areas: Municipalities and urban centers generate large quantities of organic waste from households, restaurants, and food processing facilities. Biogas plants in urban and suburban areas can help divert this waste from landfills, reduce methane emissions, and contribute to local energy production.

- Wastewater Treatment Plants: Sewage treatment plants handle organic waste in the form of sewage sludge. Biogas produced from anaerobic digestion of sewage sludge can be used to power the treatment plant itself or sold back to the grid, offsetting energy costs and reducing greenhouse gas emissions.

- Industrial Facilities: Industries such as food processing, breweries, distilleries, and paper mills produce organic waste streams that can be suitable feedstock for biogas production. Installing biogas plants at these facilities can help manage waste, reduce disposal costs, and provide a renewable energy source for on-site use.

- Landfills: Biogas can also be produced from the decomposition of organic waste in landfills. Landfill gas recovery systems capture methane emissions from decomposing waste and convert it into biogas for energy generation. This helps reduce greenhouse gas emissions from landfills while also producing renewable energy.

- Rural Communities: Biogas plants can provide decentralized energy solutions for rural communities that may not have access to centralized energy grids. They can utilize locally available feedstock such as agricultural waste or livestock manure to produce biogas for cooking, heating, and electricity generation.

- Renewable Energy Projects: Biogas plants can be integrated into renewable energy projects, such as solar or wind farms, to provide continuous energy generation. By diversifying the energy mix, biogas plants can enhance the reliability and resilience of renewable energy systems.

- Developing Countries: In regions with limited access to modern energy services, biogas plants can play a crucial role in improving energy access and promoting sustainable development. Small-scale biogas digesters can provide clean cooking fuel and lighting for households, reducing reliance on traditional biomass fuels and improving indoor air quality.

How is required Bio Gas Plant

Establishing a biogas plant involves several steps, from planning and design to construction and operation. Here’s an overview of how a biogas plant is typically established:

- Feasibility Study: Conduct a feasibility study to assess the viability of the biogas project. This includes evaluating the availability and suitability of feedstock, estimating potential biogas production, analyzing economic feasibility, and identifying potential risks and challenges.

- Site Selection: Choose a suitable location for the biogas plant, considering factors such as proximity to feedstock sources, access to utilities (e.g., water, electricity), transportation logistics, environmental considerations, and regulatory requirements.

- Design and Engineering: Develop detailed engineering plans and specifications for the biogas plant. This involves selecting appropriate anaerobic digestion technology, designing the layout of the facility, sizing equipment (e.g., digesters, gas storage, gas treatment systems), and integrating safety and environmental controls.

- Permitting and Regulatory Compliance: Obtain necessary permits and approvals from regulatory authorities for the construction and operation of the biogas plant. This may include environmental permits, land use permits, building permits, and compliance with health and safety regulations.

- Procurement and Construction: Procure equipment, materials, and services required for construction. Construct the biogas plant according to the approved engineering plans, following best practices for safety, quality control, and environmental protection.

- Startup and Commissioning: Once construction is complete, start up the biogas plant and commission each component to ensure proper functioning. This involves testing equipment, optimizing process parameters, and conducting safety checks. It may also include training staff on plant operation and maintenance procedures.

- Operation and Maintenance: Begin commercial operation of the biogas plant and continue to monitor and manage its performance. This includes daily operation of equipment, monitoring process parameters (e.g., temperature, gas production), troubleshooting issues, and performing routine maintenance tasks to ensure optimal efficiency and reliability.

- Quality Control and Assurance: Implement quality control measures to ensure the production of high-quality biogas and digestate. Monitor gas composition, digestate nutrient content, and environmental impacts to ensure compliance with quality standards and regulatory requirements.

- Community Engagement: Engage with stakeholders, including local communities, feedstock suppliers, regulatory agencies, and other relevant parties, to communicate about the biogas plant, address concerns, and foster positive relationships.

- Continuous Improvement: Continuously evaluate and improve the performance of the biogas plant through ongoing monitoring, data analysis, and implementation of process optimization measures. This may involve upgrading equipment, implementing new technologies, or expanding capacity as needed.

By following these steps and incorporating best practices in project management, engineering, and operations, a biogas plant can be successfully established to produce renewable energy, manage organic waste, and contribute to sustainable development goals.

case study on Bio Gas Plant

Certainly! Let’s consider a case study of a biogas plant established in a rural farming community.

Title: Rural Biogas Plant for Sustainable Energy and Waste Management

Background: The case study focuses on a rural community located in an agricultural region where livestock farming is a primary economic activity. The community faced challenges related to waste management from livestock manure, which posed environmental and health concerns. Additionally, access to reliable electricity was limited, and the community sought sustainable energy solutions to reduce dependence on fossil fuels.

Objectives:

- Manage livestock manure effectively to mitigate environmental pollution and odors.

- Generate renewable energy from biogas to meet the community’s electricity needs.

- Improve soil fertility by utilizing digestate as organic fertilizer for agricultural purposes.

- Enhance economic opportunities and livelihoods within the community.

Implementation:

- Feasibility Study: A feasibility study was conducted to assess the potential for establishing a biogas plant in the community. This included analyzing feedstock availability, estimating biogas production, evaluating economic viability, and identifying suitable technologies.

- Site Selection and Design: A suitable location for the biogas plant was identified, considering factors such as proximity to livestock farms, access to utilities, and environmental considerations. The design of the biogas plant included anaerobic digesters, gas storage facilities, gas treatment systems, and digestate management infrastructure.

- Stakeholder Engagement: Collaboration with local farmers, community leaders, and relevant stakeholders was essential to garner support and ensure the success of the project. Community meetings and consultations were held to discuss the benefits of the biogas plant and address any concerns.

- Construction and Commissioning: Construction of the biogas plant commenced following regulatory approvals and permits. Skilled labor and local contractors were employed for construction activities, with an emphasis on safety and quality. Once construction was completed, the plant was commissioned, and operational testing was conducted to ensure functionality and performance.

- Operation and Maintenance: The biogas plant began commercial operation, with trained personnel responsible for day-to-day management and maintenance. Routine monitoring of process parameters, gas production, and digestate quality was carried out to optimize performance and ensure compliance with regulatory standards.

Outcomes:

- Environmental Benefits: The biogas plant effectively managed livestock manure, reducing odors and environmental pollution. Methane emissions from manure decomposition were mitigated, contributing to greenhouse gas reduction efforts.

- Renewable Energy Production: Biogas generated from anaerobic digestion was utilized to produce electricity, providing a reliable and sustainable energy source for the community. This reduced reliance on fossil fuels and improved energy security.

- Soil Fertility Improvement: Digestate produced as a byproduct of biogas production was used as organic fertilizer, enhancing soil fertility and crop yields in agricultural fields. This closed-loop approach to waste management supported sustainable farming practices.

- Economic Development: The biogas plant created job opportunities within the community, including plant operation, maintenance, and feedstock supply. Additionally, revenue generated from electricity sales and digestate fertilizer contributed to economic growth and livelihood improvement.

Conclusion: The establishment of a biogas plant in the rural farming community demonstrated the potential for sustainable energy production, waste management, and economic development. By leveraging local resources and engaging stakeholders, the project addressed environmental challenges, improved energy access, and enhanced livelihoods, contributing to the overall well-being and resilience of the community.

This case study highlights the importance of community involvement, effective planning, and integrated approaches to addressing complex socio-environmental challenges through biogas technology.

White Paper On Bio Gas Plant

Title: Harnessing Renewable Energy and Sustainable Waste Management: A White Paper on Biogas Plants

Abstract:

Biogas, a renewable energy source produced through anaerobic digestion of organic matter, presents a promising solution to the dual challenges of energy insecurity and environmental pollution. This white paper provides an in-depth exploration of biogas plants, focusing on their technology, benefits, applications, and future prospects. By examining case studies, technical specifications, and policy considerations, this paper aims to inform policymakers, stakeholders, and the general public about the potential of biogas plants in advancing sustainable development goals.

Table of Contents:

- Introduction

- Understanding Biogas: Technology and Process

- Benefits of Biogas Plants

- Environmental Benefits

- Energy Security and Decentralization

- Economic Opportunities

- Waste Management Solutions

- Applications of Biogas

- Electricity Generation

- Heat Production

- Vehicle Fuel

- Fertilizer Production

- Case Studies: Successful Implementation of Biogas Projects

- Rural Communities

- Agricultural Sector

- Industrial Applications

- Urban Waste Management

- Technical Considerations

- Types of Anaerobic Digesters

- Feedstock Selection and Pre-treatment

- Gas Treatment and Utilization

- Digestate Management

- Policy and Regulatory Framework

- Incentives and Subsidies

- Standards and Certification

- Environmental Regulations

- Challenges and Future Outlook

- Feedstock Availability and Quality

- Technological Advancements

- Financial Viability

- Public Awareness and Acceptance

- Conclusion: Advancing Sustainability through Biogas Plants

Introduction:

Biogas, a versatile renewable energy source, holds immense potential in addressing pressing global challenges such as climate change, energy insecurity, and waste management. As the world transitions towards a low-carbon economy, biogas plants offer a sustainable pathway to reduce greenhouse gas emissions, promote energy access, and create economic opportunities. This white paper provides an overview of biogas technology, highlighting its benefits, applications, and implementation strategies across various sectors.

Understanding Biogas: Technology and Process:

Biogas is produced through the anaerobic digestion of organic materials such as agricultural waste, livestock manure, food scraps, and sewage. Microorganisms break down the organic matter in the absence of oxygen, producing biogas composed primarily of methane (CH4) and carbon dioxide (CO2). Anaerobic digestion occurs in sealed containers called digesters, which come in various designs such as batch, continuous stirred-tank reactors (CSTR), plug flow, and fixed film digesters.

Benefits of Biogas Plants:

Biogas plants offer a multitude of benefits, including environmental, economic, and social advantages. By capturing methane emissions from organic waste and converting them into energy, biogas plants mitigate greenhouse gas emissions and reduce reliance on fossil fuels. Additionally, biogas production promotes energy security, decentralization, and rural development, while also providing opportunities for waste management and nutrient recycling.

Applications of Biogas:

Biogas can be utilized for electricity generation, heat production, vehicle fuel, and fertilizer production. In off-grid areas, biogas-powered generators provide reliable electricity, while biogas boilers and heaters offer sustainable heating solutions. Biogas can also be upgraded to biomethane and used as a clean transportation fuel. Furthermore, digestate produced from biogas plants serves as a nutrient-rich fertilizer for agriculture, closing the nutrient cycle and improving soil health.

Case Studies: Successful Implementation of Biogas Projects:

Several case studies illustrate the successful implementation of biogas projects across different sectors and geographic regions. Examples include rural biogas plants in developing countries, agricultural biogas systems on livestock farms, industrial applications in food processing and wastewater treatment, and urban biogas projects for municipal waste management.

Technical Considerations:

Key technical considerations for biogas plant design and operation include the selection of appropriate anaerobic digestion technology, feedstock pre-treatment, gas treatment and utilization methods, and digestate management practices. Factors such as feedstock availability, composition, and seasonal variations influence the design and performance of biogas plants.

Policy and Regulatory Framework:

Government policies and regulations play a crucial role in supporting the deployment of biogas plants. Incentives such as feed-in tariffs, tax credits, grants, and renewable energy certificates can stimulate investment in biogas projects. Standards and certification schemes ensure the quality and safety of biogas production, while environmental regulations govern emissions and waste management practices.

Challenges and Future Outlook:

Despite its potential, the widespread adoption of biogas technology faces several challenges, including feedstock availability, technological limitations, financial barriers, and public awareness. Addressing these challenges requires a multi-stakeholder approach involving policymakers, industry stakeholders, financial institutions, and research institutions. Technological advancements, supportive policies, and increased public awareness are key drivers for the future growth of biogas plants.

Conclusion:

Biogas plants represent a sustainable solution for addressing energy, environmental, and waste management challenges. By harnessing renewable energy from organic waste, biogas technology contributes to climate change mitigation, promotes energy access, and supports rural development. To realize the full potential of biogas, collaboration among governments, industry stakeholders, and civil society is essential to overcome barriers and accelerate the transition towards a more sustainable energy future.

Industrial application of Bio Gas Plant

Industrial applications of biogas plants encompass a wide range of sectors where organic waste is generated as a byproduct of manufacturing processes. Here are some examples:

- Food and Beverage Industry: Food processing plants, breweries, wineries, and distilleries produce large quantities of organic waste such as fruit and vegetable residues, spent grains, and wastewater. Biogas plants can utilize this waste as feedstock to produce biogas for on-site energy generation, reducing reliance on fossil fuels and lowering operational costs.

- Pulp and Paper Industry: Paper mills and pulp manufacturing facilities generate organic waste streams such as wood chips, bark, and black liquor. Anaerobic digestion of these waste materials in biogas plants can produce biogas for heat and power generation, supplementing or replacing traditional fossil fuel-based boilers and reducing greenhouse gas emissions.

- Chemical and Pharmaceutical Industry: Chemical manufacturing plants and pharmaceutical facilities produce organic byproducts and wastewater streams that can be treated in biogas plants. Biogas production from these waste streams not only provides renewable energy but also helps in the treatment and disposal of hazardous organic compounds, improving environmental sustainability and regulatory compliance.

- Textile Industry: Textile manufacturing processes generate wastewater containing organic contaminants such as dyes, solvents, and fibers. Anaerobic digestion of textile wastewater in biogas plants can help in wastewater treatment while producing biogas for energy recovery. This approach reduces the environmental impact of textile production and provides a renewable energy source for the industry.

- Dairy and Livestock Processing: Dairy farms and livestock processing facilities produce organic waste in the form of manure, wastewater, and feed residues. Biogas plants on these farms can anaerobically digest manure and other organic waste, producing biogas for electricity generation, heating, and process steam. Additionally, the digestate produced can be used as fertilizer, closing nutrient cycles and improving soil health.

- Municipal Solid Waste Management: Industrial parks and municipalities with centralized waste treatment facilities can incorporate biogas plants for the anaerobic digestion of organic fractions of municipal solid waste (MSW). Biogas produced from MSW can be used to generate electricity, heat, or biomethane for injection into the natural gas grid, contributing to waste diversion and renewable energy targets.

- Wastewater Treatment Plants (WWTPs): Industrial wastewater treatment plants produce sludge as a byproduct of wastewater treatment processes. Anaerobic digestion of sludge in biogas plants can produce biogas for energy recovery, offsetting electricity and heating demands of WWTPs. This approach enhances the sustainability of wastewater treatment operations and reduces operational costs.

- Agro-Industrial Complexes: Agro-industrial complexes, which integrate various agricultural and industrial processes, can benefit from the installation of biogas plants to manage organic waste streams and generate renewable energy. By co-digesting diverse feedstocks, such as crop residues, animal manure, and agro-industrial byproducts, these complexes can achieve synergies in waste management and energy production.

In summary, biogas plants offer versatile solutions for industrial sectors to manage organic waste sustainably, reduce environmental impact, and harness renewable energy resources. These applications not only improve operational efficiency and cost-effectiveness but also contribute to the transition towards a more circular and sustainable economy.