Uncategorized

5”s” Japanese method of housekeeping

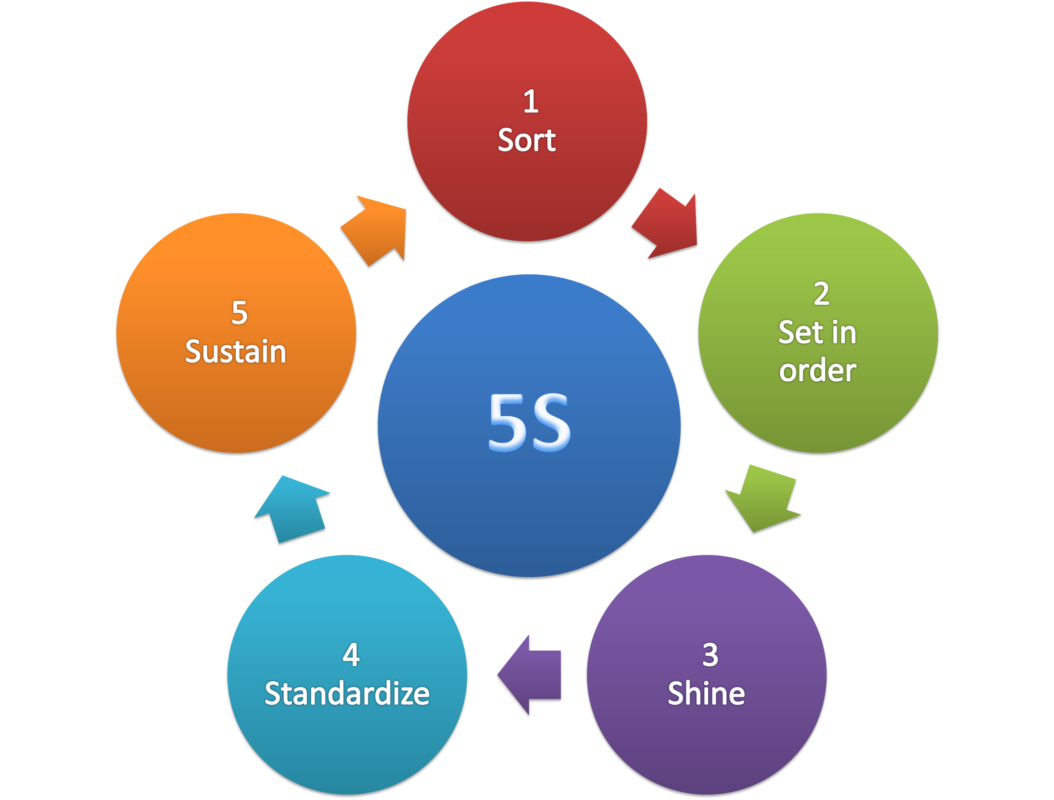

5S: what do mean these letters more and more used by companies ?

5S is a method of work organized in 5 stages with the goal of significantly improving the order and cleanliness.

5S are particularly effective because they want to improve the housekeeping of your workshops and the rest of your premises in order to obtain the following advantages :

Sort (seiri 整理)

1S – a red tag area containing items waiting for removal.

Seiri is sorting through all items in a location and removing all unnecessary items from the location.

Goals:

- Reduce time loss looking for an item by reducing the number of unnecessary items.

- Reduce the chance of distraction by unnecessary items.

- Simplify inspection.

- Increase the amount of available, useful space.

- Increase safety by eliminating obstacles.

Implementation:

- Check all items in a location and evaluate whether or not their presence at the location is useful or necessary.

- Remove unnecessary items as soon as possible. Place those that cannot be removed immediately in a ‘red tag area’ so that they are easy to remove later on.

- Keep the working floor clear of materials except for those that are in use for production.

Set in order (seiton 整頓)

Seiton is putting all necessary items in the optimal place for fulfilling their function in the workplace.

Goal:

- Make the workflow smooth and easy.

Implementation:

- Arrange work stations in such a way that all tooling / equipment is in close proximity, in an easy to reach spot and in a logical order adapted to the work performed. Place components according to their uses, with the frequently used components being nearest to the workplace.

- Arrange all necessary items so that they can be easily selected for use. Make it easy to find and pick up necessary items.

- Assign fixed locations for items. Use clear labels, marks or hints so that items are easy to return to the correct location and so that it is easy to spot missing items.

Shine (seiso 清掃)

3S – cleanliness point with cleaning tools and resources.

Seiso is sweeping or cleaning and inspecting the workplace, tools and machinery on a regular basis.

2S – simple floor marking.

(Sometimes shown as Straighten)

Goals:

- Improves the production process efficiency and safety, reduces waste, prevents errors and defects.

- Keep the workplace safe and easy to work in.

- Keep the workplace clean and pleasing to work in.

- When in place, anyone not familiar to the environment must be able to detect any problems within 15 metres (50 ft) in 5 seconds.

Implementation:

- Clean the workplace and equipment on a daily basis, or at another appropriate (high frequency) cleaning interval.

- Inspect the workplace and equipment while cleaning.

Standardize (seiketsu 清潔)

Seiketsu is to standardize the processes used to sort, order and clean the workplace

Goal:

- Establish procedures and schedules to ensure the repetition of the first three ‘S’ practices.

Implementation:

- Develop a work structure that will support the new practices and make it part of the daily routine.

- Ensure everyone knows their responsibilities of performing the sorting, organizing and cleaning.

- Use photos and visual controls to help keep everything as it should be.

- Review the status of 5S implementation regularly using audit checklists.

Sustain/self-discipline (shitsuke しつけ)

Shadow board (with tools’ outline) and worker’s movement that is being used in production floor

Shitsuke or sustain is the developed processes by self-discipline of the workers. Also translates as “do without being told”.

Goal:

- Ensure that the 5S approach is followed.

Variety of applications

5S methodology has expanded from manufacturing and is now being applied to a wide variety of industries including health care, education, and government. Visual management and 5S can be particularly beneficial in health care because a frantic search for supplies to treat an in-trouble patient (a chronic problem in health care) can have dire consequences. Although the origins of the 5S methodology are in manufacturing, it can also be applied to knowledge economy work, with information, software, or media in the place of physical product.

In lean product and process development

The output of engineering and design in a lean enterprise is information, the theory behind using 5S here is “Dirty, cluttered, or damaged surfaces attract the eye, which spends a fraction of a second trying to pull useful information from them every time we glance past. Old equipment hides the new equipment from the eye and forces people to ask which to use”.