Technical Supervision Of Manufacture Of Certified Product

Technical supervision of the manufacture of a certified product involves overseeing and ensuring that the manufacturing processes comply with the established standards, specifications, and regulations set forth by relevant certification bodies or authorities. This supervision aims to guarantee the quality, safety, and consistency of the product being manufactured.

Here’s a step-by-step approach to technical supervision of manufacturing a certified product:

1. **Understanding Certification Requirements**:

– Familiarize yourself with the certification standards and requirements applicable to the product.

– Understand the technical specifications, quality criteria, and testing methods specified by the certification body.

2. **Pre-production Assessment**:

– Review and approve the manufacturing processes, equipment, and materials to ensure they meet the certification standards.

– Conduct a preliminary audit or assessment of the manufacturing facility to identify potential areas of non-compliance.

3. **Quality Control and Inspection**:

– Implement a robust quality control system to monitor the manufacturing processes and product quality.

– Conduct regular inspections and audits during production to ensure adherence to the certification requirements.

– Verify the quality of raw materials, components, and finished products through testing and analysis.

4. **Documentation and Record-keeping**:

– Maintain comprehensive documentation of all manufacturing processes, inspections, tests, and quality control measures.

– Keep records of any deviations, corrective actions, or non-conformities identified during the manufacturing process.

– Ensure that all documentation is accurate, up-to-date, and readily available for review by the certification body or authorities.

5. **Training and Skill Development**:

– Provide training to manufacturing staff on the certification standards, quality requirements, and best practices.

– Ensure that employees are competent and capable of performing their roles effectively and in compliance with the certification standards.

6. **Continuous Improvement**:

– Continuously monitor and evaluate the manufacturing processes to identify opportunities for improvement.

– Implement corrective and preventive actions to address any non-conformities or quality issues.

– Regularly review and update the quality management system to ensure its effectiveness and relevance.

7. **Communication with Certification Body**:

– Maintain open communication lines with the certification body or authorities overseeing the certification process.

– Provide regular updates on the manufacturing progress, quality control measures, and any changes that may affect the certification status.

– Cooperate with the certification body during scheduled audits, inspections, or assessments.

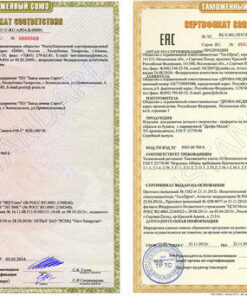

8. **Final Certification and Compliance**:

– Prepare and submit all required documentation, test reports, and evidence of compliance to the certification body for final review.

– Address any feedback or concerns raised by the certification body promptly and effectively.

– Once all requirements are met and verified, obtain the certification or approval for the manufactured product.

Remember, technical supervision is a continuous process that requires diligence, attention to detail, and commitment to quality. It’s essential to maintain a proactive approach, anticipate potential challenges, and take proactive measures to ensure compliance with certification standards throughout the manufacturing process.

Reviews

There are no reviews yet.