Sale!

QS 9000/TS 16949 : Quality System for Automotive Industry

Original price was: ₹25,000.00.₹20,000.00Current price is: ₹20,000.00.

QS 9000 and TS 16949 are quality management system (QMS) standards specifically developed for the automotive industry. These standards are designed to ensure that automotive suppliers meet the high-quality requirements and expectations of the automotive manufacturers.

Here’s a brief overview of both standards:

### QS 9000

QS 9000 (Quality System Requirements) was a quality standard developed by the Big Three automakers in the United States: General Motors, Ford, and Chrysler. It was introduced in 1994 to harmonize their respective quality system requirements into a single set of expectations for their suppliers.

**Key Features of QS 9000:**

1. **Process Approach:** Emphasizes the importance of process control and continuous improvement.

2. **Preventive Action:** Focuses on identifying potential issues before they become problems.

3. **Supplier Development:** Encourages suppliers to develop their quality systems and improve their performance.

4. **Statistical Methods:** Requires the use of statistical methods for quality control and improvement.

5. **Documentation:** Emphasizes the importance of well-documented procedures and records.

### TS 16949

TS 16949 (Technical Specification) was introduced in 1999 as an international standard, replacing QS 9000. It was developed by the International Automotive Task Force (IATF), which consists of automotive manufacturers and their respective trade associations from around the world.

**Key Features of TS 16949:**

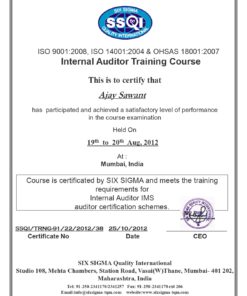

1. **Alignment with ISO 9001:** TS 16949 is based on ISO 9001 but includes additional automotive-specific requirements.

2. **Customer Satisfaction:** Emphasizes the importance of meeting customer requirements and enhancing customer satisfaction.

3. **Continuous Improvement:** Requires ongoing improvement of processes, products, and systems.

4. **Risk Management:** Focuses on identifying and managing risks related to quality, safety, and compliance.

5. **Supplier Management:** Requires effective management of suppliers and their performance.

### Transition to IATF 16949

In 2016, TS 16949 was updated and replaced by IATF 16949. IATF 16949 incorporates the requirements of ISO 9001:2015 and includes additional automotive-specific requirements developed by the IATF.

**Key Features of IATF 16949:**

1. **Risk-Based Thinking:** Emphasizes proactive identification and management of risks.

2. **Leadership Commitment:** Requires strong leadership commitment to quality and customer satisfaction.

3. **Product Safety:** Focuses on ensuring the safety and compliance of automotive products.

4. **Supply Chain Management:** Emphasizes the importance of managing and improving the automotive supply chain.

5. **Performance Metrics:** Requires the establishment and monitoring of key performance indicators (KPIs) to measure and improve performance.

### Benefits of Implementing QS 9000/TS 16949/IATF 16949:

1. **Improved Quality:** Enhances product quality and reliability.

2. **Customer Satisfaction:** Increases customer satisfaction and loyalty.

3. **Operational Efficiency:** Improves operational efficiency and reduces waste.

4. **Competitive Advantage:** Provides a competitive advantage in the automotive industry.

5. **Global Recognition:** Enhances global recognition and acceptance by automotive manufacturers worldwide.

In summary, QS 9000, TS 16949, and IATF 16949 are quality management standards that help automotive suppliers meet the stringent requirements of the automotive industry. Implementing these standards can lead to improved quality, increased customer satisfaction, and a competitive advantage in the marketplace.

Reviews

There are no reviews yet.