Sale!

Lead Auditor Training on ISO 13485

Original price was: ₹20,000.00.₹15,000.00Current price is: ₹15,000.00.

ISO 13485 is an international standard that outlines the requirements for a quality management system (QMS) for medical devices. If you’re looking to become a lead auditor for ISO 13485, you’ll need to undergo specific training to understand the standard thoroughly and develop auditing skills.

Here’s an overview of the training typically required for becoming a lead auditor for ISO 13485:

### 1. **Understand ISO 13485 Standard**

– **Scope and Purpose**: Learn the scope and purpose of ISO 13485, which covers the design, development, production, and servicing of medical devices.

– **Requirements**: Study the specific requirements outlined in the standard, such as management responsibility, resource management, product realization, and measurement, analysis, and improvement.

### 2. **Auditing Principles and Practices**

– **Audit Types**: Understand the different types of audits, including internal audits, supplier audits, and third-party audits.

– **Audit Process**: Learn the stages of an audit, from planning and preparation to conducting the audit, reporting, and follow-up.

– **Audit Techniques**: Gain knowledge of various auditing techniques, including interviewing, observation, and document review.

### 3. **Lead Auditor Skills**

– **Communication**: Develop strong communication skills to effectively interact with auditees, ask relevant questions, and provide feedback.

– **Problem-Solving**: Enhance problem-solving and analytical skills to identify non-conformities and recommend corrective actions.

– **Ethical Considerations**: Understand the importance of impartiality, integrity, and confidentiality in auditing.

### 4. **ISO 13485 Documentation**

– **Documentation Requirements**: Familiarize yourself with the documentation requirements of ISO 13485, including quality manual, procedures, work instructions, and records.

– **Document Review**: Learn how to review and assess documentation during an audit to ensure compliance with the standard.

### 5. **Practical Exercises and Case Studies**

– **Mock Audits**: Participate in mock audits to practice auditing skills in a controlled environment.

– **Case Studies**: Analyze real-world case studies to understand the application of ISO 13485 requirements in different scenarios.

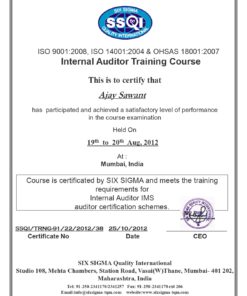

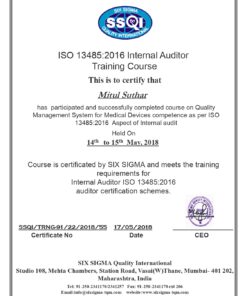

### 6. **Certification**

– **Training Courses**: Enroll in a lead auditor training course accredited by a recognized certification body.

– **Examination**: Successfully pass the lead auditor examination to demonstrate your knowledge and understanding of ISO 13485 and auditing principles.

– **Experience**: Gain practical auditing experience by participating in actual audits under the guidance of experienced auditors.

### Recommended Steps:

1. **Research Training Providers**: Look for training providers or organizations that offer lead auditor training for ISO 13485. Ensure that the training is accredited by a recognized certification body.

2. **Enroll in Training**: Once you’ve selected a training provider, enroll in the lead auditor training course.

3. **Prepare and Study**: Dedicate time to prepare and study the ISO 13485 standard, auditing principles, and practices. Take advantage of study materials, resources, and practice exams provided by the training provider.

4. **Attend Training Sessions**: Participate actively in training sessions, practical exercises, and case studies to enhance your understanding and auditing skills.

5. **Take the Examination**: After completing the training, take the lead auditor examination to assess your knowledge and understanding of ISO 13485 and auditing principles.

6. **Gain Experience**: Gain practical auditing experience by participating in actual audits and working with experienced auditors to further develop your skills and expertise.

7. **Maintain Certification**: Keep your certification current by fulfilling any ongoing requirements or continuing education needed to maintain your lead auditor status.

By following these steps and investing time and effort in training and practical experience, you can become a qualified lead auditor for ISO 13485 and contribute to ensuring the quality and safety of medical devices.

Reviews

There are no reviews yet.