1 day training on GMP Certification

₹10,000.00 Original price was: ₹10,000.00.₹5,000.00Current price is: ₹5,000.00.

A one-day training on Good Manufacturing Practice (GMP) certification can provide a foundational understanding of GMP principles and requirements. Here’s a suggested outline for such a training:

Title: Introduction to Good Manufacturing Practice (GMP) Certification

Duration: 1 Day

Objective:

- Provide participants with an overview of GMP principles and their importance in ensuring the quality and safety of pharmaceuticals, food, cosmetics, and other regulated products.

- Familiarize participants with the requirements for GMP certification and how to implement them effectively within their organizations.

Agenda:

- Introduction to GMP

- Definition and importance of GMP in regulated industries.

- Historical context and evolution of GMP standards.

- Regulatory bodies overseeing GMP compliance (e.g., FDA, EMA, WHO).

- Key Principles of GMP

- Personnel: Training, hygiene, and responsibilities.

- Premises: Facility design, maintenance, and cleanliness.

- Equipment: Calibration, maintenance, and validation.

- Materials: Raw material control, storage, and handling.

- Documentation: Record-keeping, SOPs, and batch records.

- Production: Process control, hygiene, and contamination prevention.

- Quality Control: Testing, validation, and release procedures.

- GMP Certification Process

- Overview of the certification process.

- Steps involved in obtaining GMP certification.

- Common challenges and how to address them.

- Case Studies and Examples

- Real-world examples of GMP implementation.

- Case studies highlighting the benefits of GMP certification.

- Lessons learned from successful GMP compliance efforts.

- Practical Exercises

- Group activities or exercises to reinforce understanding of GMP principles.

- Review of sample documentation (e.g., SOPs, batch records).

- Q&A session to address specific queries or concerns.

- Best Practices for GMP Compliance

- Tips for maintaining GMP compliance on an ongoing basis.

- Importance of continuous improvement and quality management systems.

- Resources and tools available for GMP implementation and compliance monitoring.

- Conclusion and Next Steps

- Summary of key takeaways from the training.

- Encouragement for participants to apply GMP principles within their organizations.

- Suggestions for further learning or resources on GMP certification.

Delivery Method:

- Instructor-led presentation with interactive elements such as discussions, Q&A sessions, and group activities.

- Use of visual aids, case studies, and real-world examples to enhance understanding.

Materials:

- Presentation slides or handouts covering key concepts and topics.

- Case studies, examples, and exercises for group activities.

- Reference materials and resources for further reading.

Evaluation:

- Participant feedback surveys to assess the effectiveness of the training.

- Evaluation of participants’ understanding through Q&A sessions and group activities.

By following this outline, participants can gain a solid understanding of GMP principles and the certification process within a one-day training session.

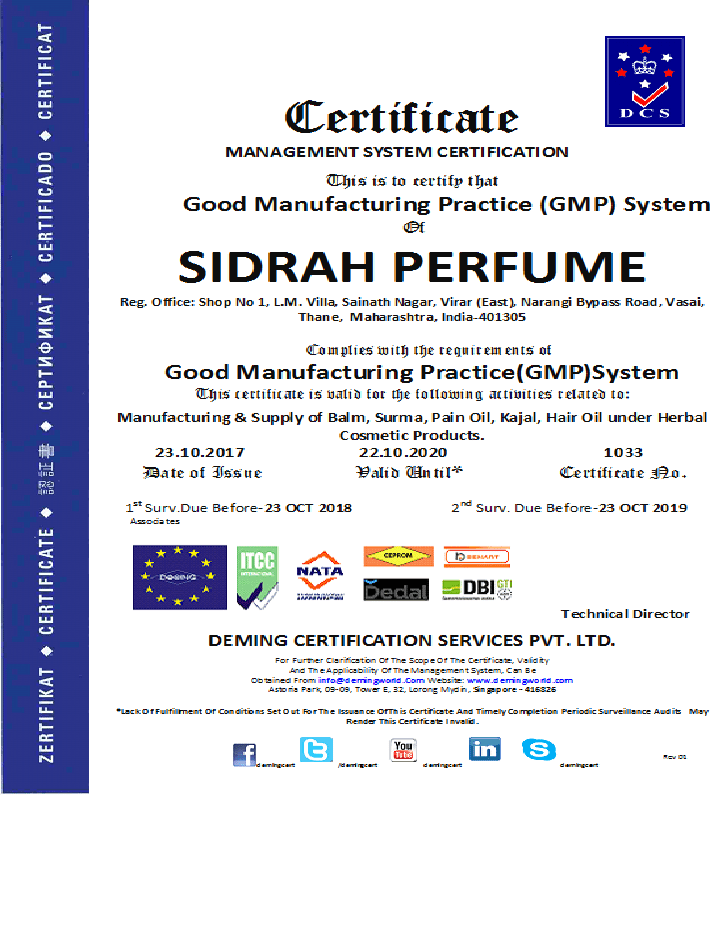

We also offer Certification Services for GMP. W. H. O. defines good manufacturing practices (GMP) as “that part of quality assurance which ensures products are consistently produced & controlled to quality standards appropriate to their intended use & as required by marketing authorization.”

GMP covers all aspects of manufacturing process that include:

Defined manufacturing process

Validated critical manufacturing steps

Suitable premises, storage, transport

Qualified & trained production and quality control personnel

Adequate laboratory facilities

Approved written procedures & instructions

Records to show all steps of defined procedures taken

Full traceability of products through batch processing records & distribution records

System for recall & investigation of complaints.

MORE Details >>GMP Certification

Reviews

There are no reviews yet.